High Energy Drying saves University 105 Days

The Fire at started in Middlesex University started in a small storage yard in the building behind the accommodation blocks. It’s in spite of the workshops of my houses that are directly behind the accommodation blocks. These buildings are old and constructive, mainly from Wood, allowing the flames to spread rapidly and making it difficult to control. Firefighters battled to control the fire in eventually had to use the blocks as a wet wall. Firefighters pump thousands of gallons of water into the building to protect them.

Unfortunately, the water protect protection, saturated the walls, floors and ceilings on every level. All the kitchen is a constructed from chipboards, which absorb massive quantities water, swelling, the most proportion. Fitted wardrobes and cupboards in the student room suffered similar fate. Set from the fire was washed in and contaminated and fabrics of furniture is.

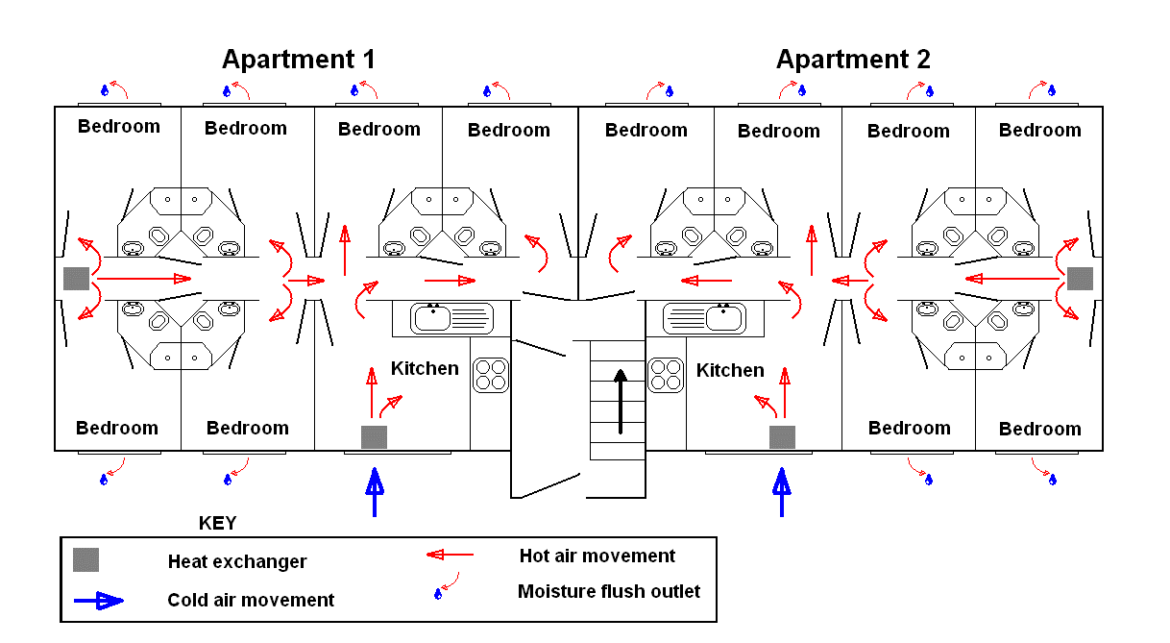

Three blocks a bit affected. Each one was forced to resign divided into eight apartments, each apartment contains six bedrooms and one kitchen. In total, each block contains 56 rooms and an internal volume of 2325 m²

Additional drying equipment, take many months to dry these buildings , this big and wet so hydronic heating system used the “pressure chamber “system as requested. Traditional drying would have taken 112 days to complete all these works, the high energy system took 7 days.

Drying Plan